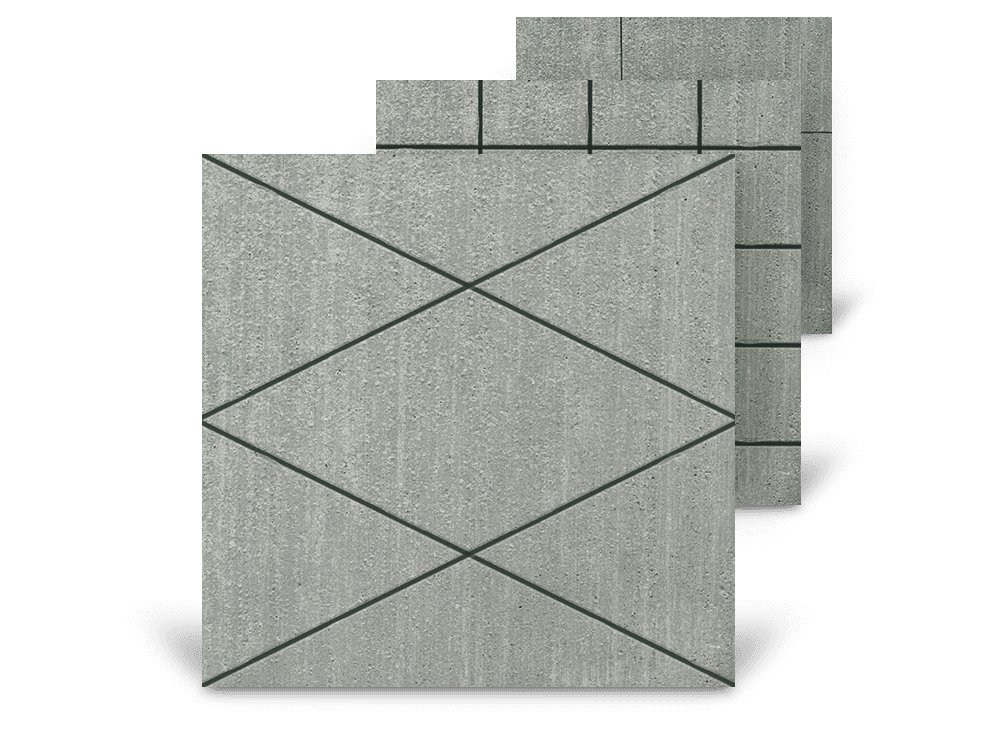

Coloured concrete for whatever look you’re after.

Wanting bright and vibrant? Or perhaps something naturally subtle is more your style? Whatever your vision, you can create the look you want with our PeterFell Coloured Concrete range.

There are over 80 colours to choose from. To make the selection process easier we’ve grouped these into seven colour categories. Each colour category gives you the choice of either PFL Special Colours or PFL Premium Colours.

The Premium Colour range provides an even more vibrant end result for your coloured concrete and is typically only about $25 more per square metre.

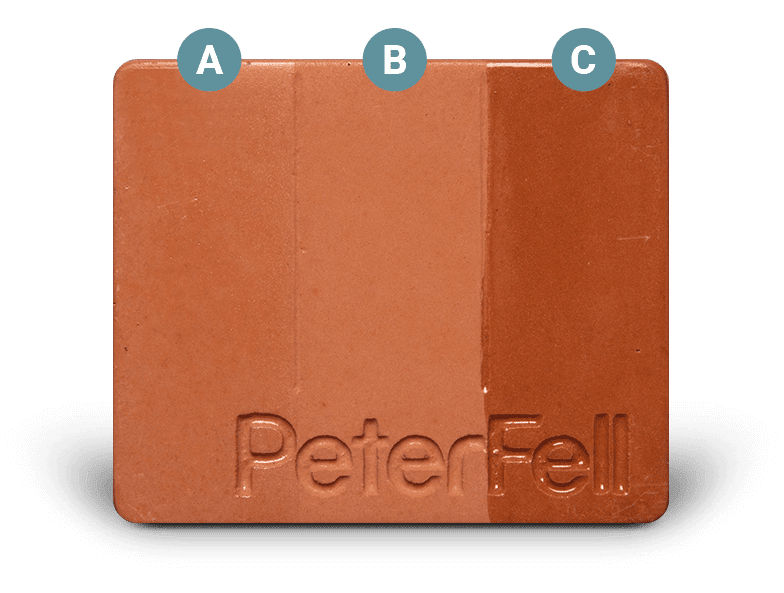

Viewing colour swatches on screen won’t give you the best indication of what the final result will be. We recommend that you view actual samples at our Auckland showroom, or at one of 150 locations around the country.

Or you can choose up to three free samples to be delivered to your door.

Please note that concrete is a natural material, so there will always be some difference in colour, texture and appearance between our sample colours and the end result. Check our Problems page for more details.

We answer common questions about coloured concrete.

How do I choose a concrete colour?

Choosing a concrete colour from the wide range available is the first step in the PeterFell System. When choosing a colour, a number of aesthetic and practical considerations need to be taken into account. The colour choice must consider the nature of integral colour that results in a natural and unique coloured floor which cannot be reproduced.

While the supplied colour is always constant, the final appearance of the colour in the concrete will always vary. We strongly recommend visiting our showroom, or contacting your local ready-mix concrete plant, to view samples of PeterFell coloured concrete before making any colour decisions.

Will the concrete colour last?

Yes. The PeterFell System mixes the liquid colour (oxide) through the concrete. It’s not a coating that sits on top of the concrete. As a result, the colour is permanent, unlike surface coatings that will chip off or wear away.

The iron oxide pigments we use for our concrete colours are sourced from Bayferrox and so are of the highest quality and have the highest light fastness values of any iron oxide materials available in the world – even under NZ’s harsh UV conditions.

The colours don’t really fade as other materials do. Iron oxides are extremely colour stable, and any slight fading that will occur would be barely noticeable, even after 25 years or more.

What factors will influence the colour of my PeterFell floor?

Every PeterFell floor is unique. While the colour dosing of the concrete is tightly controlled, the final colour will be affected by a number of elements:

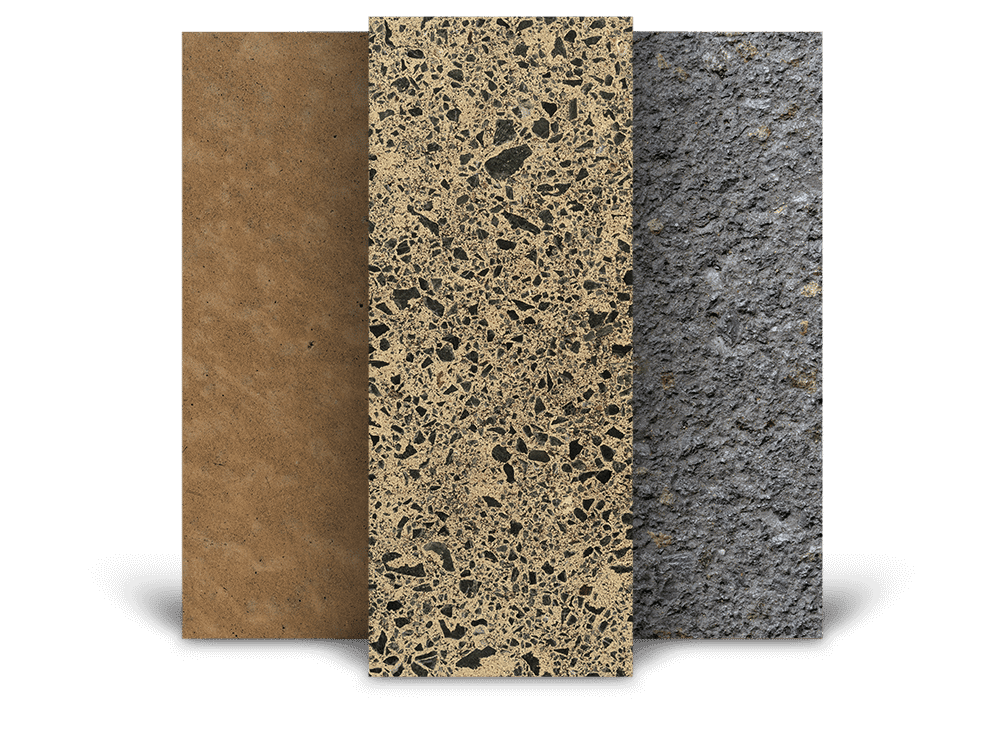

- The Concrete. Different cements, aggregates or admixtures will impact on the concrete colour. Site conditions, placement and the drying of the concrete will influence the final colour too.

- Texture. Textured surfaces tend to make the colour darker and more matt, while on smooth surfaces the colour appears lighter and glossier.

- Sealers. Sealing protects the concrete from staining and marking and also enhances the colour. Different sealers will have a different impact on the final colour so it’s important you consider this before making your final choice.

- Environment. The area where the concrete will be used and its surrounding environment will influence the concrete colour – exactly the same as for paint. The amount and type of light reflected on the concrete surface changes the appearance. So do the surrounding décor and furnishings.

- Aggregate. In any concrete where the aggregate (stones) are visible, it’s this aggregate that will be the main aesthetic component – which in turn will have an effect on the final look of the colour.

Can I get concrete colour samples?

Yes, you can request up to three free samples and we’ll deliver them to your door. We can provide you with test pots of PeterFell Concrete Sealers too (there’s a small charge for this). Alternatively, you can visit our Auckland showroom.

How is the concrete coloured?

The PeterFell System uses an integral colour method, where the colour is mixed throughout the concrete. Because the colour is literally part of the concrete (and not just a surface coating), it’s there permanently – it won’t fade, chip off or wear away.

How is the concrete colour dosed?

Each PeterFell Special Colour has a specific dose rate. This dose rate cannot be altered as it will affect the colour. This dose rate is calculated as a percentage of the cement content of the concrete i.e. most colours are dosed at 5% by weight of cement. As the cement content of concrete varies depending on type and strength of concrete and will vary for the same concrete between suppliers (and even between plants from the same supplier), the amount of oxide required can only be calculated once the concrete details have been finalised.

The key information required is the cement content of the concrete, as it is from this that all dosing is calculated. We have cement content details of all major concrete companies and can accurately calculate all dose rates and oxide requirements.

PeterFell Special Colours are manufactured specifically for each job. They are batched for specific load sizes to simplify dosing at the plant. This also reduces any risk of incorrect colour dosing. You need to notify us immediately if load sizes are changed as this will affect colour dosing and the colour will need to be re-batched.

All buckets are clearly labelled with bucket weight, load number, number of buckets per load, and total oxide required per load. All oxides are weighed to an accuracy of 0.01 kg, and all mixes are swatch tested prior to dispatch to ensure absolute accuracy and quality.

Here’s an example:

Require PFL Special Oxide 155 for 9 m3 of standard 20 MPa concrete to be batched into 1 x 5 m3 load and 1 x 4 m3 load.

- PFL 155 is dosed at standard 5% by weight of cement

- The cement content of the concrete is 240 kg per m3

- The cement content can be obtained directly from the concrete supplier or from Peter Fell Ltd.

Oxide Dose rate = 240 kg/m3 x 5% = 12 kg/m3

Total oxide required = 12 kg/m3 x 9 m3 = 108 kg

Oxide per load:

- For 5 m3 load = 12 kg/m3 x 5 m3 = 60 kg (3x 20 kg pails)

- For 4 m3 load = 12 kg/m3 x 4 m3 = 48 kg (3x 16 kg pails)

Gelato range

Our Gelato range is made using Aalborg® white cement. While white cement allows lighter and brighter colours, it adds extra cost and is not available from all concrete manufacturers.

Pastel range

Our Pastel range is made using Aalborg® white cement. While white cement allows lighter and brighter colours, it adds extra cost and is not available from all concrete manufacturers.

Order your free samplesSuperWhite

Our SuperWhite range is made using Aalborg® white cement. While white cement allows lighter and brighter colours, it adds extra cost and is not available from all concrete manufacturers.

Order your free samples